Is your product development process stuck in the slow lane? Imagine cutting your development time in half, slashing costs, and impressing clients with jaw-dropping prototypes. Sounds like magic? It’s not. It’s 3D technology at work.

Key Points:

- Faster product development with 3D models.

- Cost-effective prototyping without compromising quality.

- Marketing materials become more dynamic and engaging.

- Easy customization for niche markets.

Speeding Up Product Development Like Never Before

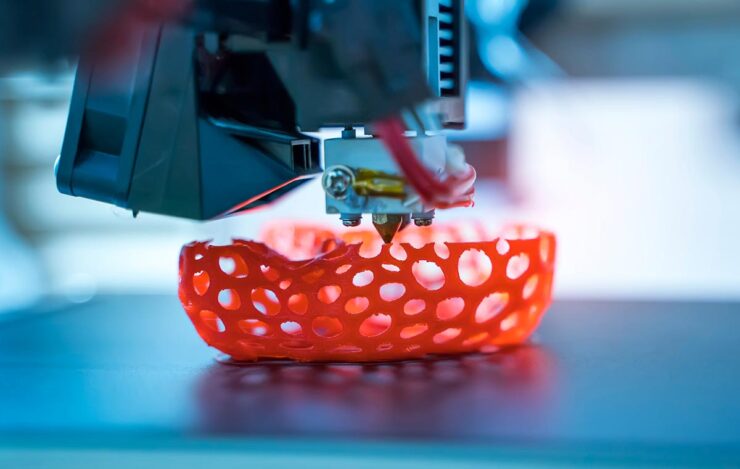

Gone are the days when creating a prototype meant endless delays and budget headaches. With companies like Print Factory, businesses can now whip up detailed prototypes without breaking a sweat. Their expert team helps match your project with the right materials and designs, saving time and resources.

Faster prototyping means quicker feedback. You can make adjustments on the fly, eliminating costly errors before hitting mass production. Imagine testing out multiple versions of a product in a single week. That’s not future talk—that’s now. The rapid iteration process not only reduces development cycles but also increases innovation. Teams can explore creative ideas without the fear of wasting months of work if something doesn’t pan out.

Cost Reduction Without Cutting Corners

Traditional methods often burn through budgets like wildfire. Material waste, expensive molds, and long labor hours add up quickly. But with advanced 3D techniques, you produce exactly what you need—no more, no less.

Why it saves money:

- No need for expensive molds.

- Less material waste.

- Lower labor costs due to automation.

- Fewer design flaws mean reduced expenses in corrections.

Small businesses, in particular, benefit from this. You can now compete with larger companies without needing deep pockets. Even startups can create professional-grade prototypes to pitch to investors or present at trade shows.

Enhancing Marketing Strategies with Physical Prototypes

A glossy brochure can only do so much. Now imagine handing a potential client a miniature version of your product. It’s tangible, memorable, and far more persuasive than slideshows or photos.

Physical models make trade shows more dynamic. They engage people, spark conversations, and leave lasting impressions. It’s marketing with a punch. Plus, these prototypes help bridge the gap between concept and reality, making it easier for clients to visualize the final product.

Key Marketing Benefits:

- Interactive product demonstrations.

- Eye-catching displays for events.

- Improved client presentations with hands-on samples.

Personalization Made Easy

Mass production often overlooks personalization. But modern techniques allow for quick changes without affecting efficiency. You can tweak designs to suit specific markets or even individual clients.

Consider custom packaging, limited-edition products, or personalized promotional items. They’re easy to create without adding significant costs. Brands that offer personalized options often see higher customer loyalty because people love products that feel tailored just for them.

Reducing Risks in Product Development

Launching a new product always carries risks. But by testing physical models first, you identify potential issues early. You can examine structural integrity, functionality, and design flaws before mass production.

This proactive approach reduces costly recalls and product failures, protecting your brand’s reputation. Plus, it builds confidence within your team and with stakeholders. When everyone can see, touch, and test a model, decision-making becomes more informed and less speculative.

Eco-Friendly Production Processes

Sustainability isn’t just a trend—it’s a necessity. Modern manufacturing reduces waste, uses less energy, and promotes recyclable materials. This eco-conscious approach aligns with today’s consumer values.

Benefits of eco-friendly processes:

- Reduced material waste.

- Energy-efficient production.

- Recyclable prototypes.

- Lower carbon footprint overall.

By adopting sustainable practices, companies not only contribute to environmental protection but also appeal to eco-conscious consumers. It’s a win-win situation for both businesses and the planet.

Practical Applications Across Industries

The versatility of 3D technology reaches beyond one sector. Here’s how different industries are using it:

- Healthcare: Creating customized prosthetics and surgical models.

- Automotive: Rapid development of car parts.

- Fashion: Designing avant-garde accessories and footwear.

- Architecture: Building detailed models for presentations.

- Education: Providing interactive learning tools.

Each industry benefits from speed, cost-efficiency, and customization. These applications demonstrate how adaptable and transformative the technology can be.

Overcoming Common Challenges in Implementation

Despite its advantages, there are some hurdles to be aware of:

- Material Limitations: Not all materials are suitable for every product. Some products may require a combination of traditional and modern techniques.

- Initial Investment: High-end equipment can be costly upfront, though long-term savings often outweigh the initial expense.

- Skill Requirements: Specialized knowledge is needed to operate equipment efficiently. Training staff or hiring skilled professionals may be necessary.

By planning strategically and staying informed, businesses can overcome these challenges and unlock the full potential of modern manufacturing.

Expanding Creativity in Design and Innovation

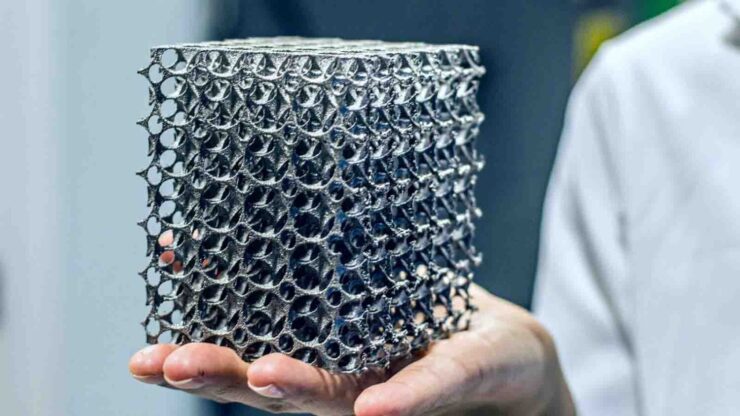

With fewer limitations on form and structure, designers can explore new creative horizons. Traditional manufacturing often imposes constraints due to mold requirements and material properties. But advanced techniques allow for:

- Complex geometries that were previously impossible.

- Lightweight structures without sacrificing strength.

- Prototypes with intricate details for precise testing.

This creative freedom leads to groundbreaking products that stand out in competitive markets.

Boosting Competitive Advantage in Global Markets

In today’s fast-paced business environment, speed and adaptability are crucial. Companies that can quickly adapt to trends, meet customer demands, and introduce innovative products have a significant edge.

How it boosts competitiveness:

- Faster time-to-market for new products.

- Ability to respond quickly to feedback and make adjustments.

- Greater flexibility in meeting diverse customer needs.

Businesses that embrace technological advancements position themselves as industry leaders.

The Future Looks Bright

Technology keeps evolving. Expect faster production times, more material options, and improved precision. Businesses that adapt will stay ahead of the curve.

Imagine a world where product development takes days instead of months. That’s not a dream—it’s the direction we’re heading. As technology continues to advance, the possibilities will only expand, offering even greater opportunities for innovation and growth.

Conclusion

3D technology has changed the game for product development and marketing. Faster prototypes, cost savings, personalized products, and eco-friendly processes make it indispensable. Businesses that embrace these innovations will thrive in a competitive market.

Ready to take your projects to the next level? Don’t just imagine the possibilities—create them.